With an integrated solution for de-oiling, mass finishing and deep cleaning of stamped and formed parts VIA Oberflächentechnik not only meets the most demanding cleanliness specifications but also achieves significant cycle time reductions and cost savings. At the same time the new system allows a high degree of operational flexibility.

VIA Oberflächentechnik, founded in 1996, is one of the leading work piece cleaning specialists in Europe. This job shop company, headquartered in Grevenbrück, has three production locations where automotive and other components are undergoing various operations like de-oiling, mass finishing, ball burnishing and deep cleaning. The in-house laboratory ensures that the treated work pieces are in full compliance with the specified cleanliness demands. Depending on the stringency of the customer requirements, some products are even packed in a dedicated cleanroom.

Mass finishing and cleaning equipment from a single source

When the company received a large order from an automotive supplier for volume cleaning of clutch carriers, for which VIA had done extensive cleaning trials with pilot production runs, the existing cleaning and mass finishing capacities were no longer sufficient and had to be further expanded.

Kai Lechner, manager at VIA, explains: “Right from the project start it was clear that we would purchase our new mass finishing system from Rösler. We were not so certain about buying the water based cleaning systems from the same supplier. But after inspecting a fully automatic combined mass finishing/cleaning system that has been successfully running at an automotive supplier for several years, we decided to purchase the complete package from one supplier, namely Rösler.”

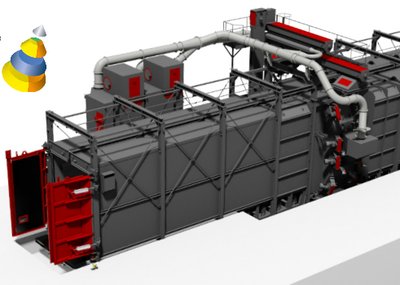

The new line consists of two cleaning units, a linear continuous flow vibrator and an automatic process water cleaning system; all interlinked with each other. VIA also purchases grinding media as well as all cleaning and finishing compounds from the equipment supplier in Untermerzbach. Kai Lechner continues: “For us it is a lot easier to deal with one partner who takes care of everything, including service and maintenance.

Interlinked process with high operational flexibility

For the de-oiling stage the clutch carriers are manually placed on the feeding conveyor of the compact spray-rinse washing machine at a 6-second cycle. They pass through two separate cleaning zones and a blow-off station. To ensure a long uptime of the cleaning liquid the system is equipped with filtration units and a coalescence separator. Since only one medium is utilized for the various cleaning processes, and since the work pieces are directly transferred into the mass finishing machine, a drying step was not necessary. Deburring and edge radiusing takes place in the linear continuous flow vibrator, type R 650/6600 DA. The process water is continuously cleaned in a Z 1000 centrifuge equipped with fully automatic sludge discharge.

After passing through the vibratory separation unit of the R 650/6600 DA vibrator the clutch carriers are transferred to the feeding conveyor of the deep cleaning unit. To ensure that the work pieces meet the stringent cleanliness requirements of “no metallic particles > 600 µm”, the carriers are manually positioned prior to entering the deep cleaning unit. They are then passed through the zones (1) cleaning, (2) rinsing and passivation. The parts are sprayed with cleaning medium from above and below. The pressure and volume of the water flow from the upper and lower spray nozzles can be separately adjusted, and the various parameters can be stored as individual programs in the equipment controls. Finally, the work pieces are passed through a drying zone, before being discharged.

For any job shop facility, operational flexibility is of utmost importance. Therefore, this equipment concept allows for the utilization of different modules in any conceivable combination. The combined cleaning/finishing system also allows for processing other work pieces with similar size and shape.

Large cost savings

Compared to the cleaning process for the pilot production with its numerous manual operations, the new system cuts the processing time in half. Concludes Kai Lechner: “A big advantage is that after an unplanned delivery stop by the customer we can resume production much more quickly and can supply the OEM with cleaned work pieces in extremely short lead times."

The interlinked equipment concept also yielded considerable cost savings. Lastly, the working environment for the employees could be greatly improved: They must no longer move the part bins between different machines but can use the saved time for more productive work.