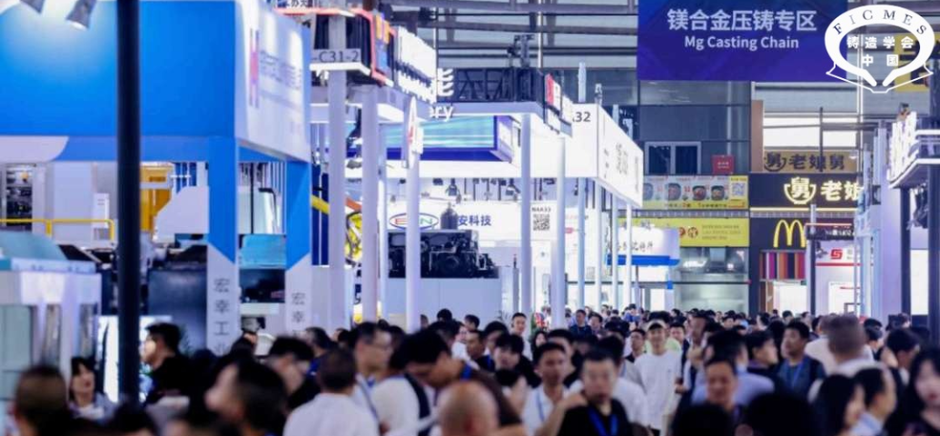

The 19th Shanghai International Die Casting and Nonferrous Casting Exhibition impressively showed where the industry is heading: more internationalization, more innovation, more high-end.

From July 16 to 18, 2025, the Foundry Division of the Chinese Mechanical Engineering Society (FICMES) presented the leading platform for die casting and nonferrous casting at the Shanghai New International Expo Center. Under the motto "Internationalization, Specialization, and High-End," the trade fair brought together the most important players in the global value chain and presented the latest technological developments.

Record participation and strong international presence

With 585 exhibitors from the fields of raw materials, plant engineering, castings, and post-processing, the trade fair recorded an increase of about 30% compared to the previous event. Around 20% of the exhibitors came from abroad, a clear signal of growing internationalization.

Hall N4 – Hotspot for magnesium alloys

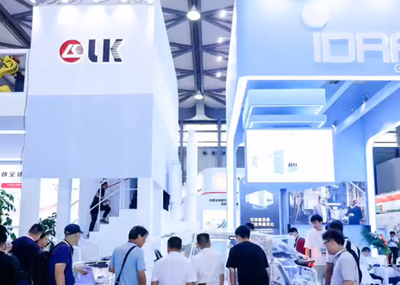

A highlight was the newly introduced Hall N4, which, as a dynamic thematic focus, attracted numerous leading companies. The focus was particularly on magnesium alloys: from material innovations to high-end applications.

Global trends and forums

Over 100 international brands presented themselves, complemented by an international pavilion. The International Die Casting Technology Development Forum provided a stage for leading companies such as Strikowestofen, Böhler, and Magma to discuss future topics like intelligent manufacturing and innovative materials.

The High-End Forum for Young Talents as well as thematic centers on 3D printing, post-processing, and high-quality die-cast parts provided additional impetus.