The work processes in foundries place special demands on the measuring equipment used, such as scales:

- Extreme temperature changes during the casting process can have a negative influence on the measuring equipment

- Reliable and precise weighing results during charging for optimum chemical composition of the melt

- Short handling times during further processing of the liquid material make additional weighing operations impossible

- The hard everyday life in the foundry, dirty and chemical fumes of the melt, must not have any influence on the accurate scales for years.

Due to these contradictory requirements, the weighing technology specialist EHP has developed the KGW foundry scale. This particularly robust as well as vibration- and shock-resistant crane scale was specially designed for foundry use in hot environments. Due to the special heat protection device and the IP69 encapsulated measuring device, the KGW crane scale can also be used for weighing material that is up to 1,600°C hot.

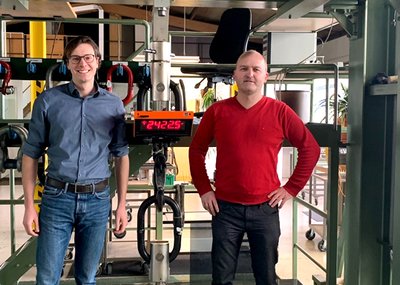

"We have a total of over 25,000 weighing systems in active use by customers worldwide - many of which are operated directly in a smelting furnace environment," says managing director Markus Ebel. "Our scales are in continuous hard use for decades in some cases. In addition to their durability, many customers particularly appreciate the precision of the crane scales."

Because the more reliably a scale weighs, the more economically a foundry can use it. Accurate weighing means less excess material used in casting. First and foremost, this saves costs and reduces the amount of material and energy used. At the same time, less material input also helps to ensure that less energy is needed for production and CO2 emissions can be reduced.

Absolutely competitive and Industry 4.0 compatible

Compared to almost all competitor products, EHP crane scales are not only a qualified measuring device for weighing due to their high safety standard, they may also be used for transporting liquid metal and raw materials. "We only use type-tested assemblies on our crane scales", says service manager Jan Friedmann, "therefore our crane scale is a real lifting device" For the operator of the crane scale this means: "Transporting goods" and "weighing goods" can be done in one pass, which saves valuable time and labour costs.

Furthermore, every EHP crane scale is also optimally prepared for digitalisation and Industry 4.0 solutions. The measurement results of the KGW crane scale can be transmitted wirelessly at any time over a distance of up to 500m to EHP crane scale accessories for further processing. From the display of the measured values on a large display, integration in existing PDA and ERP systems to automation by means of integration in PLC systems, the possibilities are almost limitless and can be presented in a customised manner.