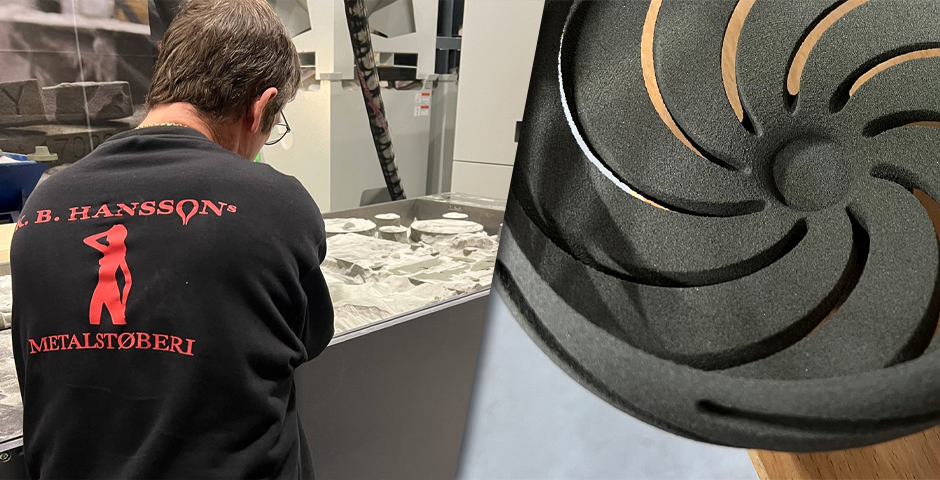

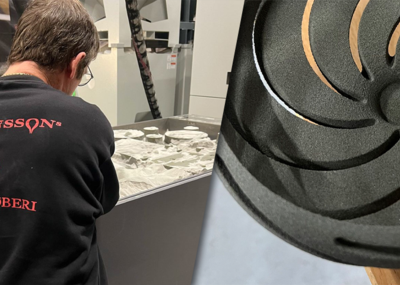

Hanssons Foundry has supplied international companies around Europe with precision prototypes and production castings for decades. The team prides itself on being a qualified partner supporting customers through the entire manufacturing process, from planning and mold preparation to casting execution.

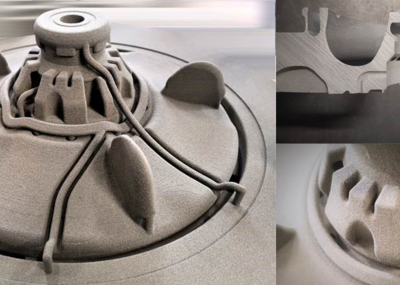

As a supplier of certified precision castings from impellers and propellers to manifolds, Hanssons aims to quickly adjust to any production need of a customer. Long core lead times that delayed deliveries led the foundry to research solutions to provide faster turnarounds.