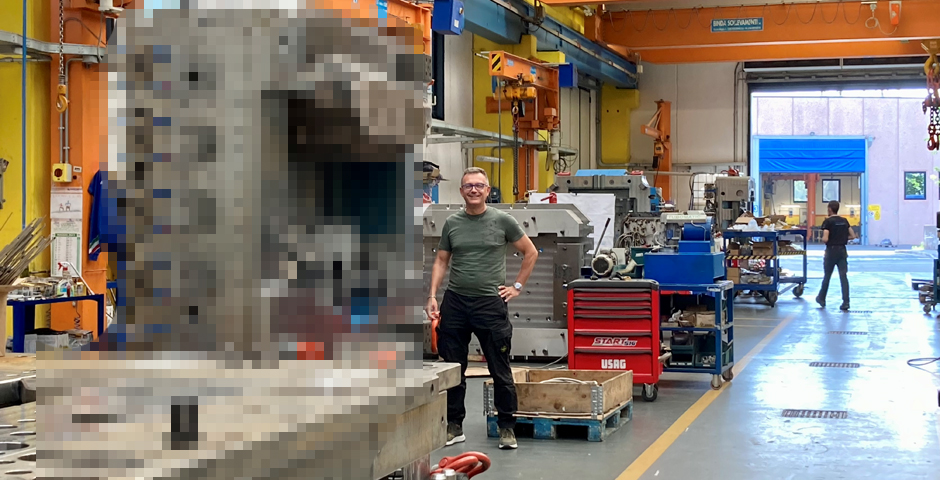

The ALUNEXT business unit operates a small foundry on its premises for the trial series production of HPDC, LPDC and LPF. Here there are die casting cells and a brand-new machine for low-pressure forging in use in the actual foundry. Three HPDC machines from 1900t to 3000t, one LPDC machine and two LPF machines.

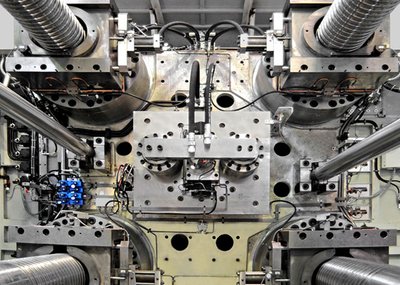

As a mold maker, COSTAMP is always at the forefront, together with its customers, when it comes to the possibilities and implementation of projects for light metals in HPDC or LPDC. Customer orientation and thus process technology and economic efficiency therefore have top priority.

Based on long experience and cooperation, technologies have also been developed that give the company a certain unique position. One example is the PiQ² simulation software, which was used to develop a proprietary filling simulation for HPDC, which has met with great interest in the market. Castle, the software application by PiQ² is developed especially for HPCD in aluminum, magnesium and zinc. We will be happy to present PiQ² and the Castle software in a separate article at another time.

Another example is the "Puzzle die" project, which leads to an increase in the economic efficiency and service life of dies that deserves the highest attention.

It is not entirely coincidental that the COSTAMP Group also plays a leading role in the field of giga tools.

As company boss Marco Corti, together with Alberto Ratti and Andreas Kant, proudly informs us, COSTAMP is one of the few suppliers of giga tools for the 6000 - 9000 ton die casting cells.

Of course, this requires the necessary space and COSTAMP will invest heavily in this area.

In combination with the strong technological basis, a highly motivated team and the most modern equipment, economic solutions are to be achieved with the greatest proximity to the customer, which meet the great challenges of the time. COSTAMP seems to be well equipped and that is why the management is relaxed and optimistic about the future.

Visit COSTAMP also at the EUROGUSS Hall 7-742

COSTAMP at a Glance

COSTAMP HPCD

Dies for High Pressure Die Casting

This is our “core business”

Dies for aluminum and magnesium parts

Customer base: 95 % automotive sector

Powertrain, EV and structural components

Giga tools

Puzzle Dies

Try-outs and production ALUNEXT

Extensive equipment for process simulation