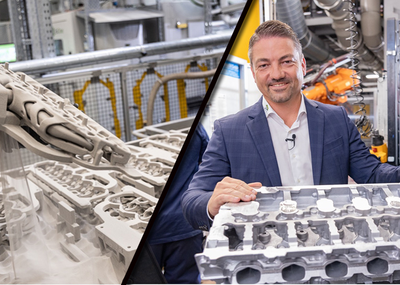

The German automaker BMW Group, for example, operates a full fleet of ExOne systems to produce cores for water jackets with inorganic binders for various combustion engines in the light metal foundry at the BMW Group Landshut plant.

At ExOne, we've always been green

Not only do our customers embrace sustainability, but we do, too! Our European headquarter in Gersthofen, Germany, is ISO 14001:2015 certified, which means that we've fulfilled the requirements for an environmental management system to enhance our environmental performance systematically. Besides, we are also a proud founding member of the Additive Manufacturer Green Trade Association (AMGTA), the only global organization bringing together manufacturing companies to develop environmentally beneficial manufacturing strategies.

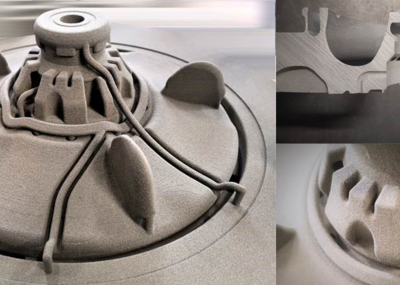

New Case Study: Topology Optimization Enhancement with Sand 3D Printing

Recently we developed a case study of topology optimization enhancement with sand 3D printing in collaboration with the foundry Maschinenfabrik Liezen und Gießerei (MFL) and the Austrian Foundry Institute (ÖGI). With sand 3D printing, the weight of rail vehicle spring cups could be reduced by 21% with proven unchanged strength and identical function. The freedom of design in 3D printing enables new complex shapes of the spring cup core packages - contributing to weight reduction. The lightweight construction not only saves on emissions associated with the ongoing operation, but also contributes to a reduction of CO2 emissions, raw materials, and the required energy in its entirety by 15% even during the manufacturing process.

Download the case study to learn more about this award-winning research project.