Almost 200 participants had come together again for the GTK Colloquium at the University of Kassel for the welcoming addresses by Prof. Dr.-Ing. M. Fehlbier, and two intensive days resulted in an interesting and varied exchange of information and an excellent networking forum.

The main topics were the transformation in die casting and sand casting, digitalization, large casting molds and giant castings in die casting, rheocasting, thixomolding, ecoCasting and much more.

The future of the foundry industry in turbulent times

In his opening address, BDGuss Managing Director Dr. Max Schumacher reported on the future of the foundry industry in turbulent times. He clearly stated that legislation and politics offer little leeway, while the transformation towards e-mobility and digitalization is already in full swing.

Despite currently rising turnover and an expected turnover of € 15.2 billion in 2023 in the German foundries, this is at most a sideways movement due to inflation. In view of the European requirements for climate neutrality and the decided ban on combustion engines until 2035, Max Schumacher also recognizes serious social changes with regard to mobility and the perception of industry in the younger generation. In this context, he also refers to the BDGuss study Casting 2035. The association will present a roadmap with a compass on how to achieve the goals to its members by March 2023 and there will be a special show on "Castainability" at GIFA.

Schumacher names the biggest challenges for the foundry industry in Germany as follows:

- Maintaining technology leadership

- Labour shortage

- Long covid of the foundry industry - Weakened financial strength

- Availability of raw materials - magnesium, aluminum, steel scrap

- Climate and energy policy

In order to defend technological leadership in Germany and Europe, it is not only necessary to invest quickly in future technology, but also to repeatedly demonstrate the perception of the foundry industry in the media with interesting examples.

The further program had a lot of interesting approaches to offer for foundrymen, students and suppliers from all sectors - here is an excerpt from the list of topics and speakers.

Productive driving in times of transformation

Dipl.-Ing. M. Wöllenstein, Head of VW Foundry Kassel

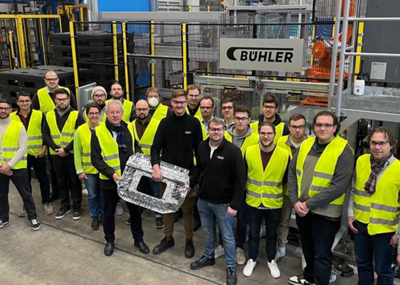

Megacasting: Opportunities - Status - Outlook

Dipl.-Ing. M. Lagler, Head of Global Product, Bühler AG Switzerland

Large Casting Molds - Challenges and Opportunities

Andreas Kant, Head Sales Department, Costamp Group Italy

Clever production of structural parts on efficient machine sizes

Dipl.-Ing. S. Padovan, HPDC Technology GmbH

Battery housings - Challenges in development and production

Dipl.-Ing. A. Hennings, Global Programs Director, Nemak, Europe

Rheocasting - The Sustainable future of HPDC

Dr. Per Jansson, Comptech Sweden

ecoCasting HD - Development of a sustainable iron casting process

Dipl.-Ing. W. Steinberg, Head of Technical Acquisition and Product Development Drive, Fritz Winter Eisengießerei

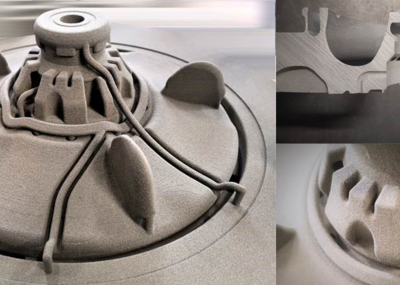

Inorganic 3D sand printing - status quo and outlook

Dipl.-Ing. E. Bader, Managing Director ExOne

Thixomolding - practical experience

Dipl.-Ing. S. Schneider, Head of Sales, Castwerk Technologies GmbH/CWT

Introduction of new products and shortage of skilled workers Digitalisation in the tension between productivity increase, cost reduction, introduction of new products and shortage of skilled workers

Dipl-Ing. J. Schmiezek, Chief Growth Officer, Tvarit GmbH

Advanced Aluminum parts @Mercedes-Benz Cars - Approach for sustainable future

Dr.-Ing. M. Pfitzer, Body-in-White Engineering, Mercedes-Benz AG

Primary Al Casting Alloys on the Way to Zero CO²

Dipl.-Ing. L. Heusler, Hydro Aluminium Deutschland GmbH

CO² balancing of die casting processes

Dipl.-Ing. N. Schwenke, PhD student Uni Kassel / GTK

Method development for the characterization of the damage mechanism of an AlSi10-based alloy on the microstructure level

M.Sc. T. Ickler, PhD student Uni Kassel

On the evening of the first day of lectures, the traditional foundrymen's evening took place again in the Metakushalle in Baunatal. Excellent food and drinks and a good atmosphere in the middle of a technical centre that is now equipped with equipment for many processes. The evening included a demonstration of 3D printing of sand cores on the ExOne S-Max.

With its university environment and proximity to VW, Kassel seems to be a good place for a small but intensive Foundry Valley in North Hesse. Thanks to Prof. Dr.-Ing. M. Fehlbier, his colleagues and the 20 or so students, it is a highly interesting setting for the further development of the foundry industry.