This structural change comes with demand for new, larger components and thus also the development of larger die-casting machines.

Demands for sustainable manufacturing processes are also becoming increasingly important. Efficient and environmentally compatible workflows along the process chain are therefore the premise for innovative and promising technologies in the industry.

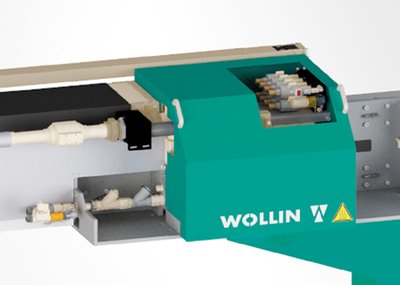

With further and new development of the proven WOLLIN spray system, WOLLIN offers solutions for precisely these requirements.

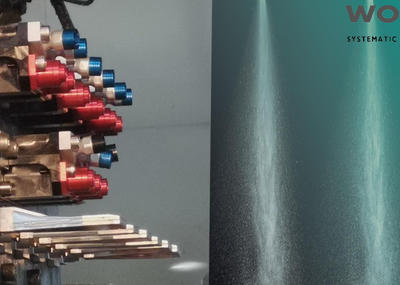

With the development of the minimum quantity spray system (MMS), which works without the addition of water to cool the mould, the concentrated release agent is sprayed on in small, minimal doses. Among other things, this achieves a high level of resource efficiency with regard to water consumption and waste water treatment. Furthermore, savings are possible in terms of mould service life, cycle time, energy costs and compressed air. As a result, spraying is more economical, efficient and sustainable.

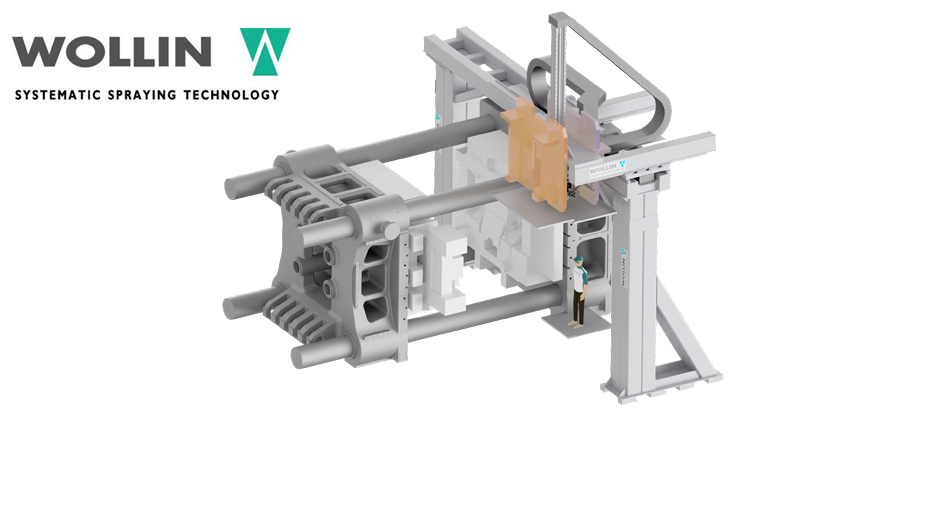

Larger moulds are accompanied with larger mould spraying tools. Large spraying tools weigh more and therefore pose great challenges for the periphery of the carrier systems. WOLLIN has various approaches for large die-casting machines and giga-presses. From a combined use of several robots, to a gantry system for fast and flexible movement of the mould with large spraying tools and a service axis for easy maintenance, to the linear spraying system newly developed especially for the giga-press, a suitable solution is available depending on the requirement. The latter linear spraying system enables simultaneous spraying of both mould halves by means of a multi-stage telescopic system for optimum cycle times with a horizontal and vertical stroke of more than 3 m each and a load-bearing capacity for spraying tools of up to 600 kg.

About Wollin

As a pioneer in spray technology, Wollin is one of the leading innovators and spray system providers for pressure die casting foundries as well as automation technology and special machinery. With its high degree of expertise and know-how in development and commitment to customer orientation, Wollin creates sophisticated solutions for tomorrow's workflows and processes. Its products are used in around 60 countries. In addition to the construction, production and office site in Lorch, Germany (headquarters), Wollin operates offices in Plymouth (USA) and Taicang/Jiangsu (China), with multiple other sales partners around the world.