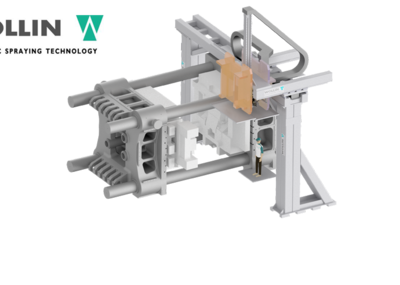

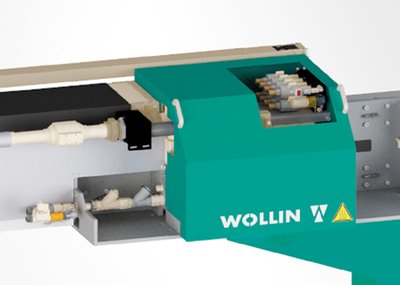

The special feature of this new spraying device is the belt drive. Standard sprayers usually use a rack-and-pinion drive, which quickly reaches its performance limit. "What we wanted was a new drive concept. And the belt drive is ideal because it does not need to be lubricated. In addition, the cycle times can be improved with the belt drive," stated Schöben. He also revealed that some customers are already interested in buying the sprayer, which is designed for minimal quantity spraying. According to Schöben, orders were already placed. (Foundry-Planet will report about the use of this new sprayer.) Apropos use: The sprayer will be installed on smaller die-casting machines that produce small parts such as door hinges or switch panels. "Another advantage of the machine is that we can transfer our expertise and our spraying and process technology from the standard cold-chamber die-casting machines to the hot-chamber area", states Schöben.