The targets of Microspraying are quite challenging and in Motultech Baraldi are investigated since long time with many experiments conducted first in our Technical Center and our “Lube Test” equipment, and after in the foundries with our customers. The reduction of the quantity of release agent applied has for sure a positive impact on the environment, on the savings of water and energy, and on the die lifetime, but require a perfect die thermal management. This is a key point that need a careful engineering of the dies during the design phase but also a careful control and monitoring during the production. How we can do that?

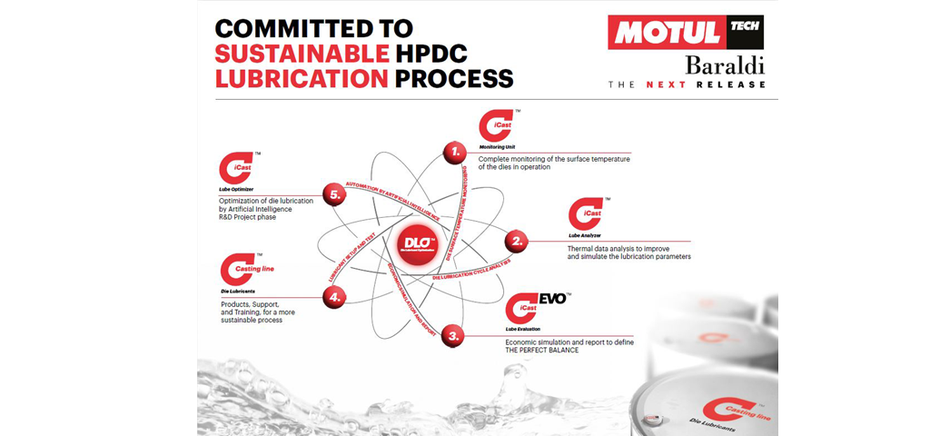

We need to monitor the complete die surface temperature during production and use such data with the software for the analysis of the thermal mapping that is called iCast Lube Analyzer. With the results of such analysis, we select the right lubricant from our range of products for microspraying application and we simulate its use with iCast EVO. With this application we can evaluate the annual savings in terms of the cost of release agent, of the cycle time reduction, the increase of production, the reduction of water use and finally the reduction of waste water disposal cost. Another important point is the technical support and professional training that our experts give to the foundry operators and process engineers.

We can therefore state that Microspraying in Diecasting requires prerequisites that ensure the thermal conditions of the dies necessary to produce castings with the required quality. The choice of lubricant type to adopt depends on the thermal conditions of the die and only thanks to the contribution of our iCast Lube Analyzer and iCast EVO technologies and the expertise of our specialists, it is possible to achieve the objectives and benefits of Microspraying.

The methodology we described is called DLO "Die Lube Optimization" and we apply it with our customers all over the world.

If you are interested to know more on this subject visit us at GIFA in Dusseldorf between 12th and 16th June at booth 11F33 or contact us: https://www.baraldi.com/en/contatti/