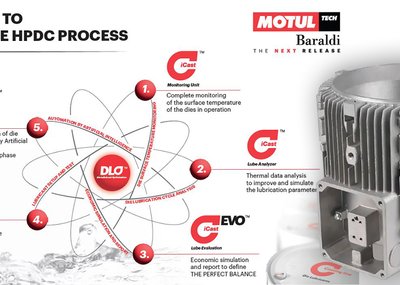

Never before has the search for sustainable and innovative solutions to lubrication problems become a categorical imperative at Motultech Baraldi. The need for greater attention to respect the environment and people's health has guided our company since 1980, and our laboratories are studying new product formulations with these objectives on a daily basis. Once the formulations have been developed, it is necessary to verify their effectiveness and efficiency by minimizing the time and costs of "testing", but at the same time acquiring and analyzing as much data as possible from the experiments carried out. For this reason, for about ten years, a physical simulator called "Lube Test" has been designed and built in our Research Center, capable of carrying out spray tests on a H11 steel mold heated to variable temperatures typical of the diecasting process, acquiring and continuously recording the temperature values on the surface and inside the mold, before and after spraying with determination of the "delta T". As for the process parameters that can be varied, and whose variations can be investigated and analyzed, there are:

- dilution ratio (%) of the release agent;

- Type of spray nozzle;

- Type of spraying (continuous or pulsed);

- Spray pressure;

- Spray angle;

- Distance between nozzle and mold.

It is also possible to evaluate characteristics such as the film-forming capacity of the lubricant and its thickness on the surface of the mold, and by means of "reverse engineering" techniques, define the heat transfer coefficients (HTC) of each lubricant, which are necessary to carry out accurate simulations in the FEM and FDM software. The use of the Lube Test has allowed us on the one hand to acquire a know-how of excellence unique in our sector, with the acquisition of data from hundreds of experiments, and on the other to be able to reproduce and simulate the conditions of process of our Customers, formulating “tailor made” lubricants upon request.

For those interested in receiving more information: https://www.baraldi.com/en/contatti