The company, always attentive to new technologies, has followed a path of updating to become an important and consolidated reality in the Italian and international industrial panorama, making use of the best plant innovations that the market makes available and choosing its own workers to support the various production, economic and environmental needs

Fonderie Palmieri is preparing to face the new challenges that the market proposes, with the awareness of having a modern, efficient and competitive structure based on 5 key points:

Quality: Achieving established goals and meeting customer requirements with high production standards

Flexibility: Organization, dynamism and optimization of services, in order to be ready for the continuous evolution of the market, guaranteeing, in addition to simple supply, an effective consultancy and design service that allows the customer to navigate through the numerous problems.

Punctuality: Being able to carry out all process steps in-house is a strategic strength that reduces waiting times for customers.

Safety: worker protection is fundamental in any business. Investments in safety are an opportunity that the company has taken to make the working environment safer and more productive.

Eco-sustainability: Great attention is paid to the environment through compliance with regulations, maximum respect for energy resources and careful management of the entire waste cycle.

Fonderie Palmieri spa, has always been aware that proposing and implementing a competitive model based on maximum quality and efficiency in terms of non-quality and social costs, is an element of primary importance. It has therefore planned and established an integrated management system in accordance with UNI EN ISO 9001:2015, UNI EN ISO 14001:2015, UNI ISO45001:2018 and UNI CEI EN ISO 50001:2018 standards to continuously ensure the conformity of its products to the customer's requirements and to the applicable legal prescriptions.

In recent years, the company has made substantial investments that have enabled it to completely renew its entire machinery fleet.

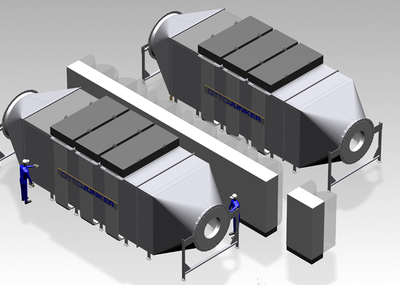

Production flexibility is ensured by two medium-frequency induction furnaces from Otto Junker GmbH with high power density. These ovens guarantee optimum energy efficiency and a production capacity of 5 tons every 48 minutes. With the medium-frequency technology, each production batch can start with a solid charge. It is therefore possible to melt different cast irons every 5-tonne batch.

In the year 2021, the melting furnaces underwent a major revamp replacing the entire control system.

In January 2017, Fonderie Palmieri installed the INDUGA JUNKER PUMA PRO 1500 melting system. This is a world first, the first machine of this generation.

The control of the material pouring works both through a mass flow verified by a weighing system and through a control of the cast iron in the casting funnel by evaluating the image of two cameras.

The temperature is measured and recorded during the entire casting process. This installation represents a fundamental step towards continuous improvement in terms of quality, safety and environment.

In addition, the installation also maintains the maximum flexibility provided by the casting system during casting.

The moulding sand is produced by a Space-Jml plant, installed in 2015. Thanks to a state-of-the-art control system, all parameters (temperature, humidity, cohesion, compactability, etc.) are constantly monitored and controlled through self-correction algorithms.

The moulds are produced by a Savelli moulding plant using FORMINPRESS technology whose bracket dimensions are as follows 900 x 700 x 350 In 2021, the moulding plant also underwent a major revamp.

All castings after cooling, stripping and demoulding are sandblasted inside by a DISA CT3 shotblasting machine (subject to revamp in 2021).

In order to meet increased customer demands with regard to lead time, the company completely renovated the deburring department in 2017.

Four KOYAMA deburring centers operating within the department are capable of deburring castings weighing up to 30 kg with high levels of quality and efficiency.

For larger and heavier castings, two automatic deburring plants are used.

There is also an automatic robotic shotblasting machine (currently being finished) that is used for cleaning internal ducts and for other local shotblasting operations in those parts (such as engine heads, compressors) that require a high degree of cleanliness and controlled surface conditions after the deburring phase.

If necessary, the parts can be heat-treated using the three furnaces in the company. All temperature curves of the treatments are recorded on dedicated servers and are supplied to the customer on request.

Another of the company's strengths is the design office where numerous technicians are able to support the customer from the early stages of the project to the delivery of samples. Numerous design software and MAGMASOFT for simulations are used.

With the support of some qualified partners, Fonderie Palmieri is able to supply fully machined and painted castings ready for insertion in assembly lines.