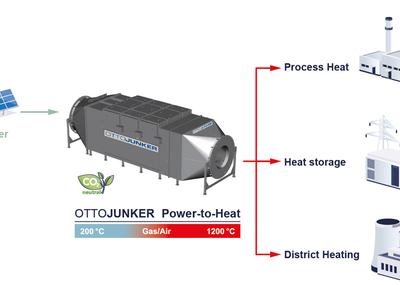

On this year’s GIFA/THERMPROCESS trade fair, OTTO JUNKER, leading supplier of foundry and thermoprocessing equipment, will present its multiTESS high temperature heat storage system which has been developed in cooperation with several industrial companies. The system allows the flexible and efficient use of renewable energies for heat and power supply to industrial companies and businesses. With the OTTO JUNKER developed Power-to-Heat modules, air with temperatures of up to 1,100°C is generated and then stored in the system. Due to the low losses, the excessive power from renewable sources with an efficiency of 98 % can be transformed into heat. Apart from that, multiTESS offers a cost efficient possibility to ensure a power and heat supply even during extended periods without solar or wind power generation. For the company, the Power-to-Heat module represents a milestone in sustainable heat and energy storage and opens new doors in high-temperature heat storage as well as the electrification and decarbonization of the industry.

Transform and store

The use of Power-to-Heat technologies (PtH) can help to increase the share of renewable energies without the power supply network and to reduce CO2 emissions by using excessive energy from renewable sources such as wind and solar energy plants for providing heating energy and transforming it into heat. PtH plants can be used in almost all branches of industry and production and reduce the primary energy consumption. By combining these systems with heat storage devices, a sustainable energy supply can be established. On top of that, systems can be used as back-up in order to maintain the supply and avoid standstills in case of failures.

For a long time, the R&D team has dealt with technologies such as PtH in order to push forward the energy revolution. In cooperation with industry partners and universities, the company focuses on creating synergies and on contributing to enhance the progress of storage-strategic developments. Erik Míček, OTTO JUNKER CEO, points out: „Many advantages can be gained both economically and ecologically. We consider it our obligation to use our expertise and our position and to interlink ourselves with others accordingly. Transformation is now”.

OTTO JUNKER - we understand transformation

The multiTESS pilot plant is the very promising result of a joint development. Since 2017, the multiTESS (multifunctional thermal power storage device) storage concept for a decentralized and flexible power and heat supply has been developed at the Solar Institute Jülich (SIJ) of the Aachen Polytechnic. Contrary to the conventional Power-to-Heat approach which generally focuses on hot water storage systems in connection with district heating, the heat in the thermal power storage device of multiTESS is stored at temperatures of up to 1,100 °C and can thus be reconverted into power in a thermal power process or directly used as heat. This is achieved by the OTTO JUNKER developed Power-to-Heat module.

Versatile ranges of application with high temperature

In combination with a heat storage device, the PtH unit reduces energy costs by the possibility to purchase and use energy at different points in time. Also, it allows a

CO2 -free production. In addition to that, waste heat unused so far can be efficiently used by overheating it, storing it at a high temperature level and eventually re-using it as process heat. Thermal oil circuits are ideally suited because they can be converted in a centralized manner. The overheating of steam and the use in drying processes are also possible.

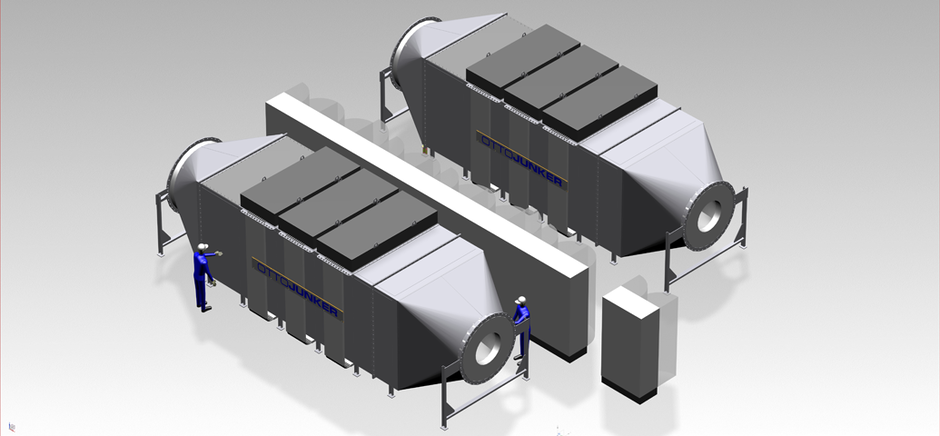

In cooperation with Dutch energy supplier Eneco Gas and PepsiCo, one of the world’s largest food producers, German Scale-Up Kraftblock has installed a high temperature storage system in a food company in Broek op Langedijk, in order to decarbonize the process heat in the potato chips factory. The system is supposed to replace gas vessels in order to avoid the use of fossil fuels and to lower emissions. The two integrated storage modules have a gross capacity of 70 MWh which means that this project uses the world’s largest commercially used high temperature heat storage system at this time. In this project which is central to the energy revolution, OTTO JUNKER is a technology partner and the supplier of the PtH modules. This initial project represents a blueprint for a huge number of application technologies.

Presentation on the GIFA/THERMPROCESS

On the GIFA/THERMPROCESS, you will have the opportunity to get informed about the wide production program of OTTO JUNKER in the thermoprocessing equipment field. Experts will be available for the exchange of ideas and will present the new Power-to-Heat module. In addition to that, the service and development team will answer questions in connection with the maintenance and modernization of existing equipment and new developments in sustainable heat and energy storage.

Visit OTTO JUNKER on booth F57 in hall 10 at the GIFA/THERMPROCESS in Düsseldorf from June 12th - 16th or contact our Head of Research and Development, Dr. Tobias Mertens.