Fonderie De Riccardis s.r.l., a family owned company that is successfully producing cast iron parts for mechanical applications for more than fifty years, has decided to start the decarbonization of their foundry and move towards to a CO2-neutral future. Therefore the existing rotary furnaces are replaced by a state of the art medium-frequency induction crucible furnace plant.

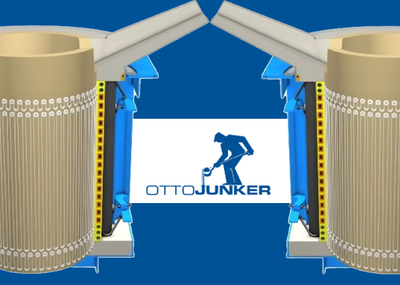

Fonderie De Riccardis therefore awarded Otto Junker GmbH with the supply and commissioning of a TRIOSYSTEM plant.

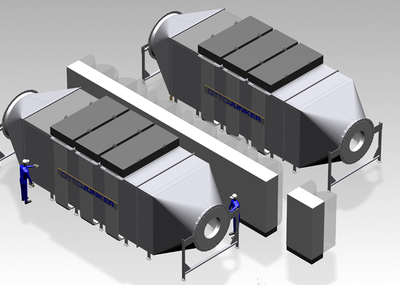

The plant is equipped with the latest technology and consists of three 12 ton induction furnaces and a common DC-converter with 2 IGBT-inverters. This technology provides the plant with the maximum possible flexibility for simultaneous melting, holding and sintering.

The 24-pulse converter with a melting capacity of 8.000 kW is supported by a factory-owned 2 MW solar yard and has an interface for communication with a higher-level energy management system. With the implemented Industry 4.0 standard, Fonderie de Riccardis is well prepared for the future digitalization of their plant.