During our on-site visit to GERLIEVA Sprühtechnik GmbH in Heitersheim, the company for spraying technology for die casting and forging companies we noticed various special features.

In particular, we were able to recognize the high level of vertical integration in many areas of the company, which is no longer offered so often these days. In a conversation with Oliver Fösel, who is head of coordination management and quality management at GERLIEVA, we want to know what advantages the high vertical range of manufacture means for the customer.

The vertical range of manufacture represents the number of stages of in-house production and is thus a measure of the vertical expansion of production. The rule is: the greater the vertical range of manufacture, the more independent the company is from external suppliers or service providers, emphasizes Fösel.

And how does the customer benefit from this?

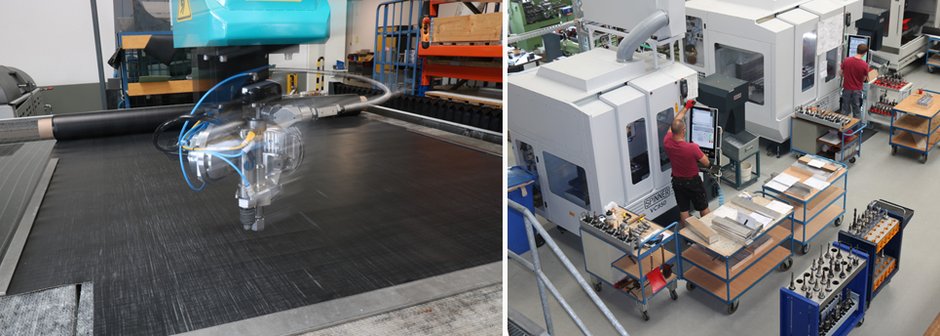

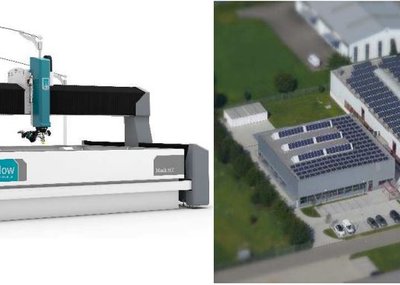

GERLIEVA is used to operating very individually and customer-specifically in the field of spraying technology for die casting and forging companies. GERLIEVA often offers special solutions and these are produced reliably and quickly for customers in Germany, Europe but also all over the world. This requires modern machinery, and GERLIEVA has invested in this in 2021, adding further machining centres and a new waterjet cutting machine.

In addition to the modern equipment, it is especially the well-trained and experienced employees who take care of the customers' wishes. Training pays off and at GERLIEVA there are many employees who have developed into real spray technology specialists in the course of their professional years.

When things have to move quickly, a well-stocked warehouse is an advantage, especially in these times. A large and broad portfolio of purchased and finished parts (motors, gears, linear guides, nozzles and spray head parts) as well as raw materials (brass rods, aluminium plates, titanium, Membrit, Frenzelit etc.).

Only in this way is it possible to act quickly, reliably and sustainably on behalf of the customer, and this has led to a vertical range of manufacture of over 90% being implemented at GERLIEVA in the meantime.

To round things off, Oliver Fösel also brings the service concept into play. In order to be able to really adapt to customer requirements and specifications, it is necessary to have access to precise system documentation. This is a top priority at GERLIEVA and is currently offered in up to 14 languages.

And how does vertical integration work in practice?

Oliver Fösel does not hesitate and immediately has a suitable example ready:

Assume the following case: We receive the following email at 10:30 in the morning: 2 pieces of diaphragm and 2 pieces of flat gasket for a die spray head with the customer's note - it's urgent!

Now, at the latest, the advantages of the high vertical range of manufacture take effect.

The customer order is immediately recorded in the ERP system and a production order is automatically triggered.

The production data record is digitally transmitted to the waterjet cutting machine. Here, the production process starts based on Membrit and Frenzelit in stock and then the membrane/flat gasket is marked for dispatch.

As early as 13.30, the invoice and delivery note are created in the ERP system together with the consignment note for the parcel service.

At 14:30, just four hours later, the desired goods can be picked up by the parcel service and are already on their way to the customer.

The secret of this reliable guarantee of success?

Regardless of whether you need spare parts for new or 25-year-old die spraying systems, customers always get an original GERLIEVA part quickly and in GERLIEVA quality, and this is due to the high level of vertical integration, because we can manufacture almost everything ourselves.

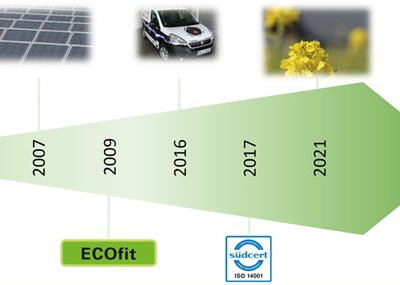

Quality, flexibility, creativity and reliability in production, these are the standards for the GERLIEVA brand and this applies today, as well as for the future, when the next generation of the Linbrunner family comes on board from January 2022.