After the casting process, there are many casting runners left which we need to be broken into smaller pieces in preparation for the next melt, because smaller pieces save costs and space.

The fettling shop becomes the starting point for the efficient and cost-effective loading of the furnace with the crushed scrap parts.

There are still foundries which instruct their workers to hammer the runners away, but soon this will be a thing of the past. It is expensive and work-intensive, a job which will be hard to fill in a well-developed and otherwise high-tech industry.

The other option is dangerous flame cutting or big crushing machines, which are expensive and take up a lot of space.

How to invest less and improve the efficiency and safety of runner breaking

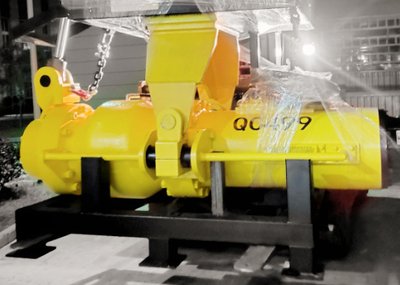

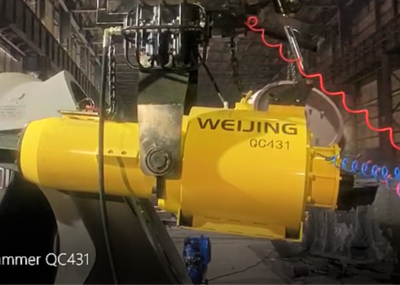

As a leader of degating equipment in China, Weijing makes useful and economic contributions to the foundry industry. After many talks with site workers in foundries, discussions, analysis and design, the new runner cutter came into the engineers`s minds.

Now, the prototype has passed the test in the foundries and the workers love the Weijing runner cutter because of its features:

- flexible operation

- big opening to cut big size runners

- cutting during degating

- no special space is needed, as the cutter can insert at different angels to cut runners directly

To get a better idea of how the Weijing Runner Cutter can improve your foundry's process, check out this video: