The renowned Swiss die-casting company ALUWAG, based in eastern Switzerland, has been supplying technology leaders competently and reliably with sophisticated die-cast components for more than 50 years.

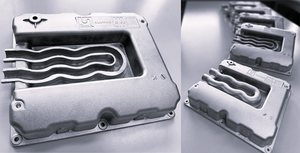

For around four years, the company has been developing gas injection technology in aluminium die casting as part of the EU research and innovation programme "Horizon 2020" and in collaboration with TIK, Magit, Surtechno and HS Aalen. The company can now put the process into practice with demostrator components for various geometries with the aim of bringing components into series production.

The process, which has already proven itself in injection moulding, is now also to be used for series processes in die casting for molten metal.

During our on-site visit to Niederbüren, we were able to talk to Raphael Hutter and Damian Föllmi about the development of gas injection technology at ALUWAG before foundry manager Nihat Atik and team leader Sujivan Srikantharajah presented the process in practice by casting the demonstrator parts.