The OCP+ extension offers the chance to identify and reduce safety risks in crucible monitoring early and, thus, improves both equipment availability and the visualization of all processes. A proactive risk analysis leads to more security and makes the production process more efficient.

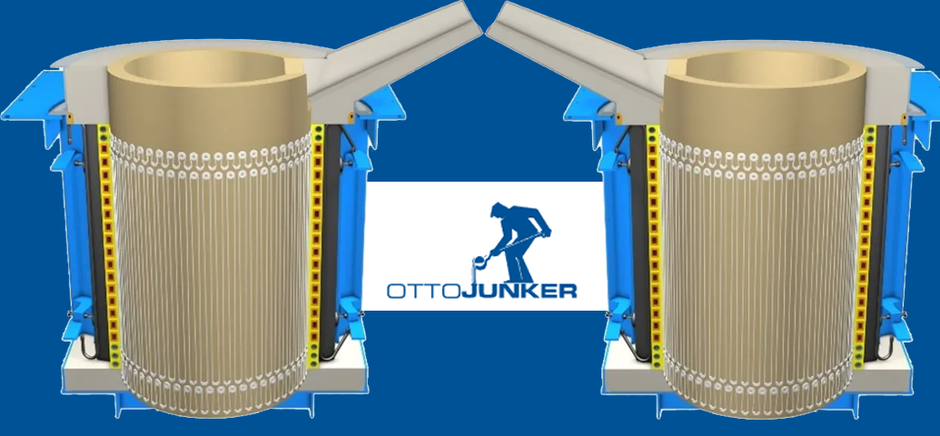

The OCP (Optical Coil Protection) system, based on fiber-optic sensors, revolutionizes crucible monitoring in induction melting furnaces. It allows the precise determination of local hot spots in the crucible, irrespective of lining type and layout. The measurement is carried out by means of the RAMAN effect which is a quantum mechanical phenomenon allowing highly accurate temperature determination.

More control in crucible monitoring

The OTTO JUNKER range of products now includes OCP+, a further development of the proven OCP system. Apart from the reliable early detection and documentation of emerging wear and crucible damage (erosions, accretions etc.), the system offers an optimized interface which is intuitive to operate. The improved visualization gives operators a clear overview at any time which allows them to act in a more proactive manner.

OCP+ offers a complete temperature monitoring during the sintering process. Its function is neither impaired by humidity nor by the melting of zinc alloys or the charging of galvanized scrap. Since OCP+ is a laser-optic temperature measuring system, it works flawlessly even in strong electromagnetic fields. The range of applications, therefore, is very wide.

Additional features of OCP+:

- One measuring unit can monitor up to two furnaces.

- Individually adaptable adjustment options for temperature warning functions and alarms (incl. LED status signal lights) allow you to act quickly.

- The playback function allows tracking of the development of crucible defects over time.

- The installation of the system is irrespective of the supplier of the coreless furnace.

- The sensor cable, which is embedded in the permanent lining of the furnace, facilitates crucible replacements and reduces maintenance costs.

„The introduction of OCP+ is a very important milestone for the induction melting furnace industry. This modern technology offers precision and safety in the temperature monitoring of coreless furnaces. With our OCP and OCP+ systems, we set new standards with regard to efficiency and reliability in crucible monitoring. These solutions not only offer an early fault detection but also help to minimize operational disruptions. We are proud to be able to offer our customers these groundbreaking systems.” – Lukasz Borkowski, Area Sales Manager – Foundry Plants.