Living the future

The participation in the GIFA/THERMPROCESS trade fair last June was one of many important steps in the transformation process of OTTO JUNKER which will raise the profile of the company and push it forward on its way to an environmentally friendly future. One main target of OTTO JUNKER’s trade fair appearance covering a booth space of more than 300 m² was to present the induction furnace as a CO2 neutral melting plant and, thus, as an environmentally friendly alternative to cupolas and gas-fired furnaces.

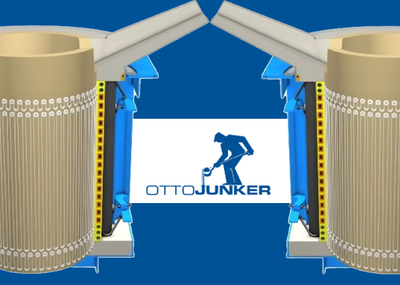

Many visitors were attracted to the OTTO JUNKER booth by the 8 ton melting furnace, in particular. JUNKER’s intention was to make foundry experts more familiar with the dimensions, functionality and quality by actually “feeling” the equipment, which is difficult to do by means of presentations or brochures alone. Also, the OCP demonstrator which shows the actual heating on the coil, generated a lot of interest. The same goes for the information stand for virtual reality safety training where spectacles could be tried which serve to train employees in a virtual environment. The JUNKER personnel on site was surprised by the number of people interested in getting an idea for themselves.

Advantages for industrial companies

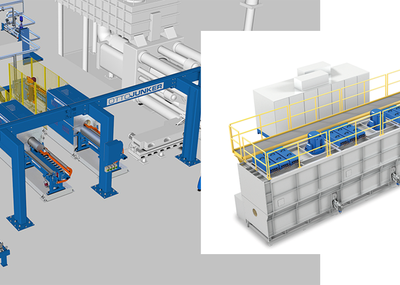

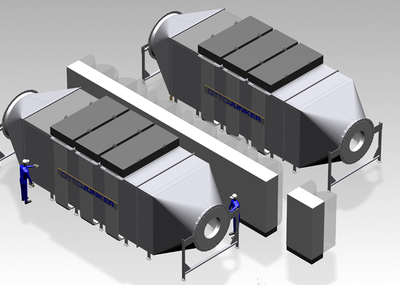

OTTO JUNKER’s CO2 neutral melting and heat treatment plants allow an environmentally friendly production by reducing greenhouse gas emissions. Further to that, they offer technical innovations and improved performance. The ongoing optimization of the equipment allows a more efficient and precise processing of metals resulting in better product quality and lower scrap rates and, thus, in improved competitiveness. Apart from that, recycling solutions for metallic scrap and batteries allow the recovery of valuable resources and thus contribute to a successful recycling economy.

New horizons and sustainable perspectives

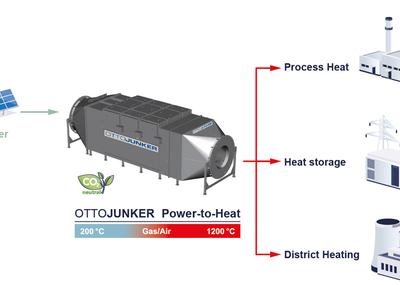

The company has clear targets in mind and will increasingly put its focus on CO2 neutral melting and heat treatment, the recycling of metallic scrap and batteries, power-to-heat applications and equipment for electrification in the coming years. In doing so, OTTO JUNKER wants to continue to be a reliable partner for industrial companies and offer innovative solutions allowing customers a sustainable production while, at the same time, increasing product quality and efficiency.

The positive feedback and encouragement by customers from all over the world during the trade fair have encouraged OTTO JUNKER to further strengthen its efforts. This is clearly reflected by the conclusion of contracts with an overall volume in the two-digit million EURO range. This significant success is the result of months of trade fair preparations and underlines the trust customers have shown in OTTO JUNKER’s quality and capabilities. It is another incentive for the company to strengthen its innovative strength and to further consolidate its position as a leading manufacturer of environmentally friendly melting and heat treatment plants.

Individual consultation and solutions

Interested parties and experts, especially those who were unable to attend the trade fair, still have the opportunity to get a detailed consultation.