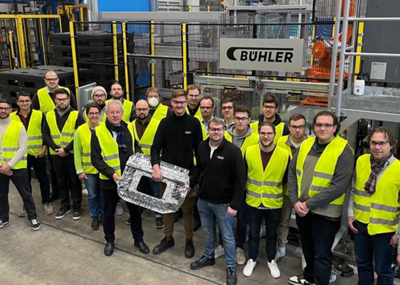

Mr Heinle's thesis, which was supervised by Prof. Lothar Kallien, focused on the casting of aluminium pipes in the die casting process. With regard to the future of the automotive industry, the technology of tube casting is becoming more and more important due to the mobility revolution. Power electronics are absolutely essential in electric vehicles. This releases a large amount of heat during operation, which must be dissipated to ensure proper functioning. Heat can be dissipated, for example, by a housing with an integrated coolant channel. At Julius Schüle Druckguss GmbH, the technology of pouring in pipes is used in the following two variants. Firstly, the casting of copper tube packs in heat exchangers made of an aluminium alloy. The heat exchangers are used in gas boilers for the property sector.

Secondly, a hollow structure made of austenitic stainless steel is cast into a housing cover made of an aluminium alloy. Nowadays, the "sustainability" and "recycling" factors are becoming increasingly important. The material combination of aluminium and steel has a disadvantage here. Mixed scrap is produced during disposal, where steel and aluminium have to be laboriously separated from each other during the recycling process. For this reason, the goal was to develop a process in which an aluminium pipe is cast without filler material. The calculation of the thermal load on the pipe was carried out in this thesis using two different calculation approaches. On the one hand, an adiabatic system was formed from the inserted pipe and the aluminium melt. A mixing temperature can be calculated in this system. Secondly, a MAGMASOFT simulation of the entire die casting process was carried out. According to the theoretical investigations, the pipe assumes temperatures of 550°C. At this temperature, the aluminium alloy has a low yield strength of < 23.5 N/mm². According to the FEM analysis, an equivalent stress of 128.6 N/mm² occurs at an external pressure of 300 bar.

Secondly, a hollow structure made of austenitic stainless steel is cast into a housing cover made of an aluminium alloy. Nowadays, the "sustainability" and "recycling" factors are becoming increasingly important. The material combination of aluminium and steel has a disadvantage here. Mixed scrap is produced during disposal, where steel and aluminium have to be laboriously separated from each other during the recycling process. For this reason, the goal was to develop a process in which an aluminium pipe is cast without filler material. The calculation of the thermal load on the pipe was carried out in this thesis using two different calculation approaches. On the one hand, an adiabatic system was formed from the inserted pipe and the aluminium melt. A mixing temperature can be calculated in this system. Secondly, a MAGMASOFT simulation of the entire die casting process was carried out. According to the theoretical investigations, the pipe assumes temperatures of 550°C. At this temperature, the aluminium alloy has a low yield strength of < 23.5 N/mm². According to the FEM analysis, an equivalent stress of 128.6 N/mm² occurs at an external pressure of 300 bar.