Sidrag AG is known as an experienced supplier for small and medium series in Switzerland. Based in Baar, Switzerland, they have been successfully producing die-cast components made of aluminum, magnesium and zinc alloys from a single source for many years. In 1998, the range was expanded to include the multifaceted material magnesium. Sidrag AG was honoured with the Innovation Award by the Canton of Zug for this successful pioneering achievement. Sidrag AG is characterised by outstanding quality, flexibility, short response times and just-in-time deliveries. In addition, the company takes care of the entire implementation of the value chain for the components in question.

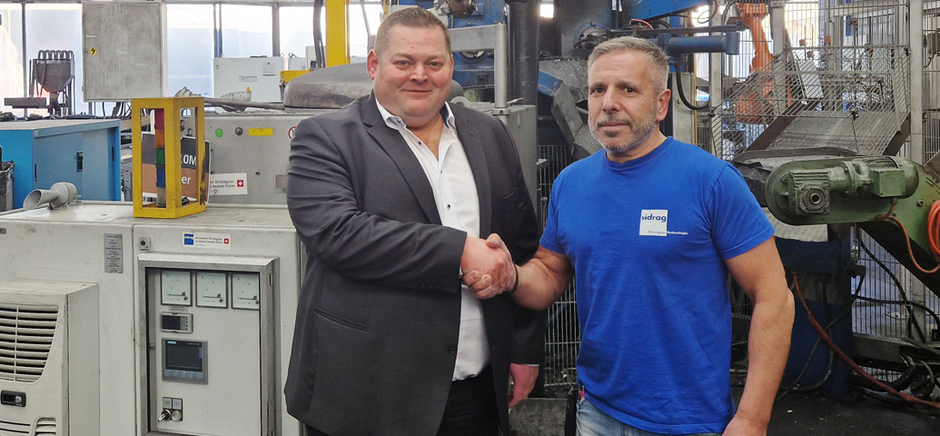

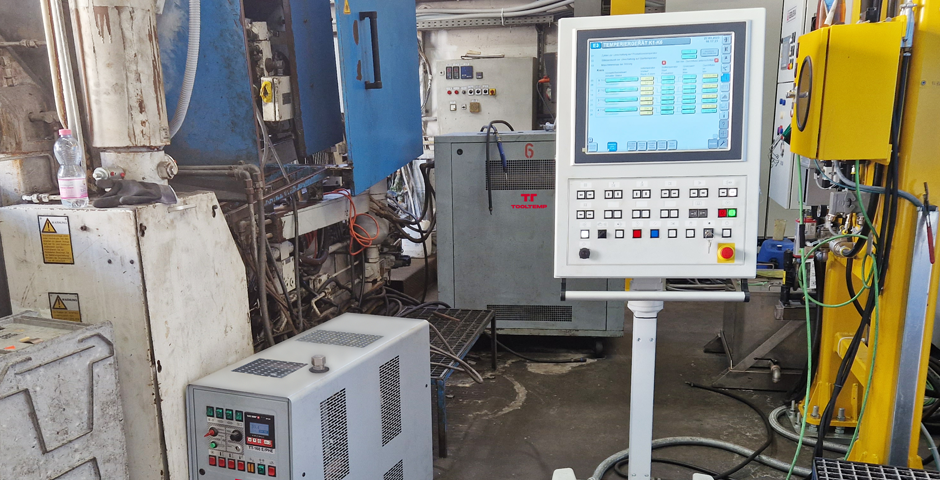

The experienced supplier Sidrag AG has been one of Tool-Temp’s valued customers for more than 25 years. Over 13 temperature control units are in daily use in the die casting foundry.

“Simplicity, trouble-free, user-friendly, the units are optimally integrated into the manufacturing process” says Luis Guil, Foundry Manager at Sidrag AG.

Tool-Temp devices optimise and stabilise the manufacturing process for Sidrag's most important industrial sectors, such as medical technology, measurement technology, optics, the construction supply industry, sensor technology, and the electrical and electronics sectors. An extremely positive development has been seen in recent years in lightweight construction, namely optics and medical technology.

Mega- or gigacasting – the production of oversized die-cast parts – is becoming increasingly important in the automotive industry, especially in vehicle body construction. However, this does not affect Sidrag, which specialises in the production of small and medium series outside of the highly competitive automotive sector. The focus lies on the development and optimisation of the classic casting cell. Throughout the casting process, the equipment is networked with peripheral devices, resulting in increased automation. This substantially increases productivity, reduces costs and creates a 30 % higher degree of staff independence so that freed-up time can be used elsewhere. Another advantage of a higher degree of automation is more consistent production processes with optimised cycle times, less waste and thus a high quality standard.